📍 Location: Copenhagen, Denmark

⏳ Employment Type: Full-time, on-site (no remote work)

📌 Reports to: Head of Technology R&D

🚀 Start Date: ASAP

Job Summary

We are seeking a Materials and Process R&D Scientist to drive innovation in material deposition, ALD and ALE process development, and new chemistries for ATLANT 3D’s products.

This role requires a strong theoretical and computational understanding of deposition processes, experience with simulation tools, and a problem-solving mindset. You will be responsible for developing and optimizing processes, working closely with customers to create tailored solutions, and ensuring seamless technology transfer into product development.

You will lead research, experimental development, and process validation, ensuring that new materials and processes align with customer needs, technical requirements, and production scalability. The role involves direct collaboration with customers, cross-functional coordination with Engineering and Applications teams, and protection and dissemination of novel material and process innovations through publications and intellectual property strategies.

Additionally, you will contribute to scientific publications, conference presentations, and marketing materials, helping to position ATLANT 3D as a thought leader in the ALD and advanced materials space.

This is an opportunity for a solution-driven scientist who thrives on tackling complex material challenges, using computational simulations to model and optimize processes, and developing breakthrough technologies in atomic-scale manufacturing.

Key Responsibilities

- Develop and execute the R&D roadmap for material and process innovations.

Perform independent research to explore new deposition chemistries, optimize material system integration, and enhance process efficiency. - Utilize computational simulations and process modeling tools such as COMSOL Multiphysics, ANSYS Fluent or Chemkin, and Molecular Dynamics (MD) simulation tools like LAMMPS, GROMACS, or VASP. to predict material behavior, surface interactions, and deposition efficiency.

- Develop and implement process models to improve predictability and control in ALD process development.

- Devise innovative solutions for ALD process challenges, ensuring optimal deposition quality and material performance.

- Develop and document process recipes, optimizing processes for new material systems.

- Lead hands-on experimental work, ensuring precise execution, testing, and validation of material systems.

Customer-Focused Problem Solving & Solution Development

- Work directly with customers to understand their material and process challenges, identifying tailored solutions.

• Translate customer needs into technical solutions, optimizing material deposition, process performance, and integration into real-world applications.

• Use computational tools and experimental validation to troubleshoot and optimize customer-specific processes.

• Act as a technical liaison, ensuring smooth collaboration between customers, ATLANT 3D’s R&D team, and product development teams.

• Propose and develop application-specific solutions, aligning new material technologies with market demands and technical requirements.

Technology Transfer & Product Integration

- Collaborate with Engineering and Applications teams to integrate new process technologies into ATLANT 3D’s product development pipeline.

• Ensure structured technology handover, providing detailed documentation, validation results, and process guidelines for seamless implementation.

• Support field applications and customer deployment, ensuring process reliability and reproducibility in real-world manufacturing.

Innovation Protection, Scientific Publications & Marketing Contributions

- Generate technical publications, patents, and conference presentations to share findings and strengthen ATLANT 3D’s innovation leadership.

• Publish research findings in peer-reviewed journals, industry publications, and conference proceedings.

• Contribute to ATLANT 3D’s intellectual property portfolio, documenting and protecting novel materials, chemistries, and processes.

• Ensure scientific discoveries and technological advancements are strategically positioned for both industry impact and competitive differentiation.

• Assist in the creation of technical content for marketing materials, including white papers, presentations, and product documentation.

Contribution to ATLANT 3D’s NF Product Tool Improvement

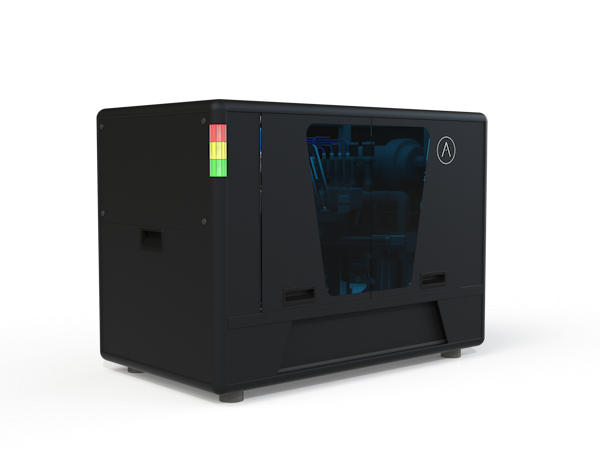

- Work with the Engineering team to enhance process control and automation capabilities in ATLANT 3D’s Nano Fabricator (NF) platform.

• Refine NF tool process parameters to optimize material deposition, system reliability, and throughput.

• Develop process monitoring and calibration strategies for continuous improvement of deposition quality.

• Validate and implement new materials and process modules into ATLANT 3D’s Nano Fabricator platform.

• Support product testing and validation, ensuring that NF platform enhancements meet customer and industry requirements.

Cross-Functional Collaboration & Supplier Management

- Collaborate with Marketing and Product teams to align materials and process R&D with customer-driven innovation and validated product requirements.

• Support supplier selection and qualification, ensuring reliable sourcing of critical materials and process components.

• Engage with external research partners, industry experts, and material vendors, staying at the forefront of emerging ALD chemistries and deposition techniques.

Must-Haves

✔ M.Sc. or Ph.D. in Inorganic Chemistry, Physics, Materials Science, or a related field with expertise in ALD, ALE processes and other material deposition and processing technologies.

✔ Strong theoretical understanding of thin-film deposition mechanisms, including reaction kinetics, adsorption/desorption processes, and nucleation growth.

✔ Experience in process modeling and computational simulations, using tools such as COMSOL Multiphysics, ANSYS Fluent or Chemkin, and Molecular Dynamics (MD) simulation tools like LAMMPS, GROMACS, or VASP.

✔ Strong hands-on experience in designing, developing, and optimizing ALD process chemistries and material systems.

✔ Proven track record in materials research, process engineering, or thin-film deposition development.

✔ Proven experience in developing advanced packaging and surface processing solutions for industrial applications, including material deposition, surface treatment, and integration processes to enhance performance, reliability, and scalability in high-tech manufacturing environments.

✔ Experience working directly with customers, translating their needs into practical process and material solutions.

✔ Excellent problem-solving skills, with the ability to identify technical challenges and develop innovative solutions.

✔ Experience publishing research in peer-reviewed journals and presenting at conferences.

✔ Ability to work in a fast-paced environment, with a results-driven mindset and strong project management skills.

✔ Full professional proficiency in English (written and verbal).

Soft Skills & Competencies

💡 Critical Thinking & Analytical Skills – Ability to analyze complex data and optimize processes.

🤝 Collaboration & Communication – Strong cross-functional teamwork with R&D, Engineering, and customer teams.

🔍 Attention to Detail – Ensuring precision in process development and scientific documentation.

🚀 Adaptability & Proactiveness – Thriving in a fast-paced, evolving deep-tech environment.

📝 Technical Writing & Presentation Skills – Ability to communicate complex research findings effectively.

What We Offer

Competitive compensation - 8% employer paid pension, delicious lunch and office snacks.

International working environment - our work language is English.

Future Growth & Impact – Supportive environment for career growth opportunities in atomic scale manufacturing, impacting multiple industries.

Clear Communication & Goal-Setting – Close collaboration with leadership to define and achieve objectives.

About ATLANT 3D

ATLANT 3D Nanosystems is pioneering the Atomic Scale Manufacturing Era, pushing the boundaries of advanced materials and micro/nanodevice production. Our mission is to drive breakthrough innovations, enabling businesses to develop disruptive applications with unmatched speed, precision, and quality. We foster a culture of collaboration, continuous improvement, and open innovation—where every team member contributes to shaping the future. We are an equal opportunity employer, committed to fostering a workplace where everyone can thrive.

Perks and benefits

This job comes with several perks and benefits

Equity package

Skill development

Social gatherings

Free coffee / tea

Free office snacks

Near public transit

Working at

ATLANT 3D